| Systems |

| Fly Ash

Pneumatic Vacuum Conveying System

Ash is conveyed pneumatically under negative pressure through specially designed valves and pipelines from Fly Ash Hoppers to –

- Nearby Silo, for eventual disposal in dry or moistened condition

- Intermediate Surge Tank, for onward dry transportation by pneumatic pressure conveying system to remote Silo.

- Wetting Unit-Collector Tank – Air Washer set, for wet disposal in slurry form.

The Wetting Unit System can be a standby for the preceding dry systems. The slurry can be Mechanical Exhausters / Vacuum Pumps are generally need for creating the vacuum. Hydraulic Exhausters, though available, are seldom need nowadays. |

|

|

|

Pneumatic Pressure Conveying System

Ash is conveyed pneumatically under positive pressure through feeder valves / Ash Transmitters and pipelines from Fly Ash Hoppers or Intermediate Surge tank to Silo for dry ash storage and onward disposal in dry or semi dry condition through tankers or open trucks.

Combined Vacuum & Pressure Conveying System

Ash is first conveyed pneumatically under negative pressure through specially designed valves and pipeline from various Fly Ash Hoppers to an Intermediate Surge Tank located near Electrostatic Precipitator. Cyclone Dust Collectors or Bag Fitters are used for separating ash from the vacuum air stream and transferring it to Surge Tank from Surge Tank is then transported pneumatically under positive pressure through separate valves, transmitter vessels and pipeline to a distant Silo for temporary storage of dry ash. |

|

Fly Ash Storage in Silo and Dry / Semi–Dry Ash Disposal System

When Dry or Semi-dry Fly Ash disposal is desired, Silos of RCC or Steel construction collect the dry ash from Conveying System either directly or through Dust Separator. Silos are provided with fluidising arrangement for easy discharge of Ash through the bottom outlets.

Ash Unloading System options from silo are :-

- Complete Dry Unloading into enclosed tankers / Wagons

- Semi-Dry unloading to open Trucks / Wagons

- Dry / Semi-Dry unloading to Belt Conveyor Systems

- Wet unloading through Feeder Ejectors for ash disposal in slurry form.

|

|

|

| Bottom Ash |

|

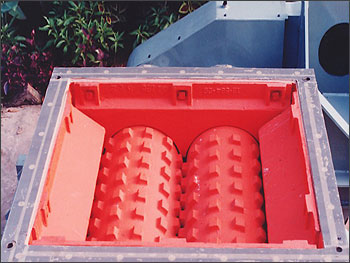

Water Impounded Hopper and Water powered Jet Pumping System

Ash and clinkers produced inside boiler furnace are quenched and stored in water impounded hopper having refractory lining. Clinkers are crushed to small places by specially designed CRUSHERS and then pumped by Jet Pulsion Pumps through pipelines directly to ash disposal area or to ash slurry sump for onward disposal through ash slurry pumps. Where Bottom Ash is required in semi-dry condition for open Truck Transportation, De-watering Bins are used for storing the Ash and taking out the conveying water from the stored ash.

Bottom Ash Disposal System with Closed Loop Water Recirculation System

DCIPS offers system suitable for generating commercially acceptable dry ash with water recirculation features which enable re-use of the transport water in repeated cycle. In this system, the ash is transported by pipeline from water impounded hopper through Crusher and Jet Pump into a dewatering tank for storage. The overflow and the drain water from the dewatering tank is taken to a settling tank and thereafter to a surge tank where relatively clean water is stored for reuse. At predetermined intervals, the dewatering tank is drained to remove all the sater from stored ash. |

Semi-dry ash is then discharged from Dewatering Bins to the truck or wagon for transportation to ash dump area or for any end use. This system can also be designed for zero discharge conditions thereby ensuring practically no outflow of the contaminated water from the system except for occasional blow-down. |

|

Submerged Scraper Conveyor / Belt Conveyor System

These systems employ continuously operating scraper conveyor or submerged belt conveyor running below boiler furnace. The trough containing the conveyor is filled with water for quenching of bottom ash. Bottom ash is discharged into a sluice trench for transportation to slurry sump or to a conveyor for storage in silo for subsequent truck transportation.

Submerged Scraper Conveyor / Belt Conveyor System

Similar to Fly Ash conveying, DCIPS offers systems for Bottom Ash and Bed Ash handling from FBC or CFBC Boilors to be transported pneumatically to Silos. Plants supplied by DCIPS are working satisfactorily.

|

|

|

|

Slurry Disposal, Water Recovery

Lean Slurry Disposal System

- With water-powered Jet Pumps for short distances

- With Centrifugal Slurry Pumps for longer distances

Water Recovery System (for lean slurry disposal)

- With collection wells, recovery water pumps, Clariflocculator, sludge pumps & clear water pumps

- Burge-mounted recovery pumps are used where appropriate

|

|

High Concentration Slurry Disposal (HCSD) System

DCIPS offers Turnkey High Concentration Slurry disposal system (HCSD) for removal of Fly Ash and Bottom Ash in Slurry form but in a very thick mixture with water, employing imported piston diaphragm type of cylinder – piston type positive displacement pumps for removal of thick slurry ( 60 – 70% concentration ) through long distance pipeline. Advantage of the system is very low water consumption and much increased ash storage level in ash dyke requiring much less ash dump area for ash disposal. Also, construction of earthen Ash Dyke is eliminated except for a low height starter dyke.

|

|

|

|